Vertical Box Transport System (VCTS)

Eastey’s Vertical Case Conveyor System allows printing on two or four adjacent sides of a case, eliminating the need for pre-printed cases or expensive labeling equipment and supplies. The adjustable width of our standard VCTS allows printing on cases between 10 x 10 inches and 33.5 x 29 inches. The larger VCTS-XL supports cases between 10 x 10 inches and 48 x 29 inches.

Automatic operation

Designed for offline box printing, the VCTS automatically feeds blank boxes through a print station ideal for installing high-resolution inkjet printers and offers the ability to print virtually anywhere on both sides of the box. Open access to the printheads facilitates maintenance and speeds up setups. The VCTS features an input hopper that holds up to 75 flat single-wall RSCs; a magazine capacity of up to 3/4 and can be easily reloaded by a single person.

Easy to program

The VCTS includes a programmable counter that records batch quantities, operating speed, and elapsed run time, allowing users to customize the case production process. The system can be easily programmed to shut off when the maximum count is reached.

Affordable versatility

Eliminate the high costs associated with pre-printed boxes by printing product-specific information directly onto blank boxes. From any perspective, Eastey's VCTS offers users an affordable solution for their box printing needs.

The correct solution

Robust design. Proven reliability. Simple operation. Its benefits are countless. In industrial operations, trust Eastey to find the ideal solution for your box conveying needs.

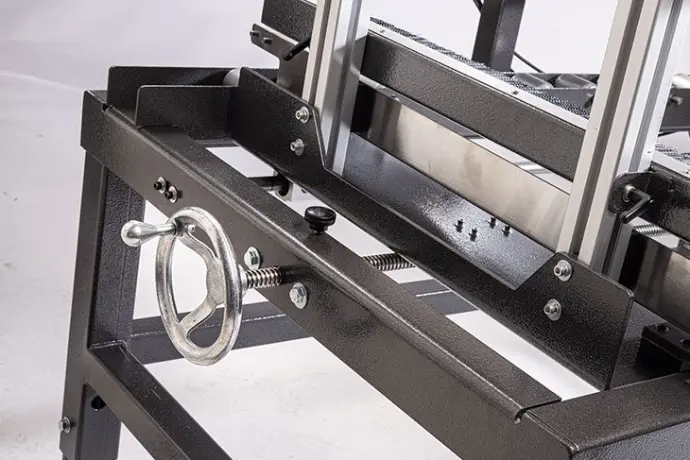

Adjustable collection container with ruler for easy switching between boxes of different widths.

Simple and robust control interface for easy operation.

The hand crank easily adjusts the width of the collection container.

The pneumatic pusher arm can be adjusted for boxes of different widths.